Today, with modern technology taking over all industries, we are more than ever committed to use industry leading technology in our designs, techniques, methods & processes in order to achieve precision in all our products.

Thus, at Eurobrass we achieve the same with our electronic mixer digital technology, lead free castings for our entire range of products, water saving aerators & cartridges and air mixing technology with rub-clean multi membrane in our showers.

Control the water flow with your hand movement.

Presenting state-of-the-art technology: The fitting detects the movement of your hand, turning on and turning off the water flow automatically.

Benefits of a mixer with an electronic motion sensor:

Save water by upto 80%. Our water saving range of taps includes a 2l/m aerator which irrespective of the inlet water pressure in the system would maintain discharge at outlet in a mixed position of 2l/m.

Benefits of Water Saving Aerators:

Saves water and energy, using 72% less water than a standard tap. Special water-saving cartridges have been developed for single lever mixer taps, which default to water saving positions that must be overridden to get stronger flows.

Benefits of Eco Water Saving Cartridges:

More water indulgence with less water usage. Eurobrass uses air mixing technology which enhances the flow by mixing air with water thus allowing the shower / faucet to work with very less water, thus reducing the amount of water used considerably.

Benefits of Air Power Technology:

Innovative British technology. This innovative technology uses a multi membrane shower structure not allowing calcium or other hard salt deposits in the face plates and thus allowing uninterrupted and smooth flow patterns.

Benefits of Rubclean Membrane:

Safer water from every faucet. At Eurobrass, latest technology allows us to bring you the same stylish faucets that you have come to rely on for years which are lead-free. We chose to modify our brass alloy and use stainless steel in order to maintain our high quality standards.

Benefits of LEAD FREE faucets:

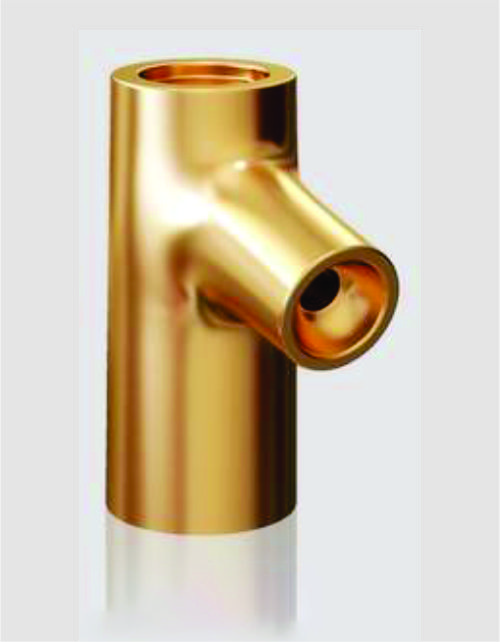

The prototyping is done in brass, an alloy of copper and zinc. Very resistant towards corrosion, easy to work on, weight = value of the product.

All the openings are machined in a single process. This way the place for the cartridge, the thread for the aerator, the support for the connecting hoses and the seat for the ceramic are machined.

The final design or form is produced. Most of the products are machined by robot today. Few parts are ground and polished by hand.

Preparation for the galvanizing process.

First layer serves as an additional protection against corrosion.

Final surface, very durable, highly valuable optic. The single components are put together to a complete the product.